04-Jan-2023 | Facts and Factors

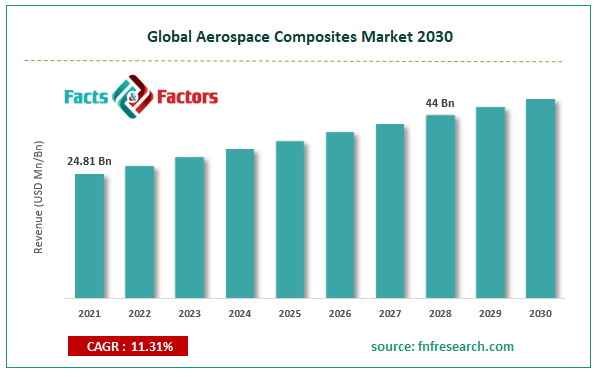

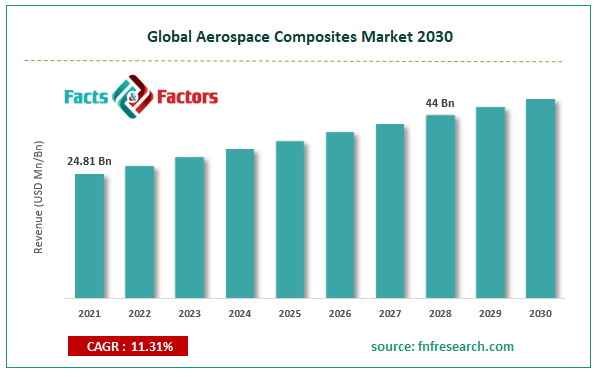

According to Facts and Factors, the global aerospace composites market size was worth around USD 24.81 billion in 2021 and is predicted to grow to around USD 44 billion by 2030 with a compound annual growth rate (CAGR) of roughly 11.31% between 2022 and 2030.

Browse the full “Aerospace Composites Market By Matrix Type (Ceramic Mix, Polymer Mix, and Metal Mix), By Manufacturing Process (Resin Transfer Molding, AFP / ATL, Filament Winding, Lay-Up, and Others), By Fiber Type (Glass Fiber Composites, Carbon Fiber Composites, Glass Fiber Optics, and Others), By Aircraft Type (Military Aircraft, Civil Helicopter, Commercial Aircraft, Business & General Aviation, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2022 – 2030" report at https://www.fnfresearch.com/aerospace-composites-market

Aerospace or the aviation industry is constantly moving toward innovation and change. These new developments intend to make flights sustainable and safer which has propelled manufacturers to make use of composites while producing helicopters, airplanes, or space shuttles. Composite materials are essentially a combination of two or more types of materials that have different chemical and physical properties. When these constituent parts are mixed together they create a new material that can perform a specific job for instance helping reduce the weight of the structure it is used in or offering resistance to corrosion and electricity. They are also known to improve the strength and stiffness of aircraft.

The main reason behind the use of composites over normal materials is that they can improve the properties of a given base material and have higher applicability. Over the years, the players in the aerospace industry have invested multiple resources in expanding the horizons of the aviation industry by exploring new products that can upgrade the effectiveness and efficiency of aircraft including commercial flights and the ones used for military or space exploration activities. The result of these efforts is the growing application of structurally advanced materials.

The global aerospace composites market is anticipated to grow owing to the growing insistence on the fuel efficiency of aircraft. Different models of airplanes have varying usage of fuel and the aviation industry is one of the highest consumers of fuel. It is known to use almost 8% of the total oil consumption across sectors. For instance, a Boeing 747 uses an approximate fuel value of 1 gallon per second. The higher fuel combustion rate in aircraft leads to increased carbon emissions.

As per estimates, around 2.57% of global carbon dioxide (CO2) emission is due to the aviation industry. Owing to such factors, the international and domestic environmental authorities have laid extreme emphasis on manufacturing fuel-efficient planes. This trait is readily offered by composites as they are not only used to create exterior parts of the plane but manufacture interior parts as well. Composites have found applications in the manufacturing of nacelles, engine blades, single aisle wings, brackets, and wide-body wings. Other factors like reduction in aircraft weight by using composites are major global market propellers. The reduction in weight, which is around 20%, has a high impact on fuel efficiency thus helping save fuel and raise its economic value.

One of the major restraints during the global market growth trajectory is the high sensitivity of composites to any defect during the manufacturing process. Skilled resources are required to produce 100% accurate composites and any small fault can lead to greater repercussions in the end since composites can completely malfunction after a certain time of constant use. This greatly impacts the use of composites as there is always a slight defect during the production process. However, composites are likely to completely rupture even in the case of the slightest deviation from standard quality.

The aggressive innovation for the development of new composites may provide expansion opportunities while growing fatal accidents in commercial flights are expected to challenge market growth.

Segmental Overview

The global aerospace composites market is segmented based on matrix type, manufacturing process, fiber type, aircraft type, and region

Based on the manufacturing process, the global market divisions are resin transfer molding, AFP / ATL, filament winding, lay-up, and others. The global market witnessed the highest growth in the automated fiber placement and tape laying (AFP / ATL) segment in 2021. This process allows for manufacturing composites in bulk quantities as compared to other methods. The total estimated cost of manufacturing a Boeing 747-8 is around USD 350.5 million and the company produces one such aircraft every 2 months.

Based on aircraft type, the global market divisions are military aircraft, civil helicopter, commercial aircraft, business & general aviation, and others. The global market registered the highest growth in the commercial segment owing to the high demand for commercial flights. The increasing investments to upgrade the total manufacturing capacity by Airbus or Boeing are a result of higher demand. Airbus delivered more than 800 aircraft in 2018.

Regional Overview

North America is anticipated to lead the global aerospace composites market owing to the higher demand for commercial flights as a result of a high standard of living and affordability of commercial flights. Europe may also register a high CAGR due to the growing demand for composites in the defense segment. Countries like Germany, France, and the United Kingdom are major producers of aircraft composites. The region accounted for over 49.5% of the total commercial aircraft production globally. Growth in Asia-Pacific is projected to be driven by the growing air traffic as well as increasing investments in developing highly advanced military-grade aircraft. The rising investment in the space exploration sector may further drive regional market growth.

Report Scope

Report Attribute |

Details |

Market Size in 2021 |

USD 24.81 Billion |

Projected Market Size in 2030 |

USD 44 Billion |

CAGR Growth Rate |

11.31% CAGR |

Base Year |

2021 |

Forecast Years |

2022-2030 |

Key Market Players |

Solvay Group, Toray Industries Ltd., SGL Group, Teijin Limited, Hexcel Corporation, Koninklijke Ten Cate BV, and others. |

Key Segment |

By Matrix Type, Manufacturing Process, Fiber Type, Aircraft Type, and Region |

Major Regions Covered |

North America, Europe, Asia Pacific, Latin America, and the Middle East &, Africa |

Purchase Options |

Request customized purchase options to meet your research needs. Explore purchase options |

Competitive Landscape

The global aerospace composites market is home to players like Solvay Group, Toray Industries, Ltd., SGL Group, Teijin Limited, Hexcel Corporation, and Koninklijke Ten Cate BV.

Recent Developments:

- In November 2021, SAMI Composites LLC announced the launch of a new manufacturing facility to push the production of composites encouraging the aerospace industry of Saudi Arabia

- In May 2022, Collier Aerospace launched new composite-related software called HyperX® Structural Analysis and Design Software

The global aerospace composites market is segmented as follows:

By Matrix Type

- Ceramic Mix

- Polymer Mix

- Metal Mix

By Manufacturing Process

- Resin Transfer Molding

- AFP / ATL

- Filament Winding

- Lay-Up

- Others

By Fiber Type

- Glass Fiber Composites

- Carbon Fiber Composites

- Glass Fiber Optics

- Others

By Aircraft Type

- Military Aircraft

- Civil Helicopter

- Commercial Aircraft

- Business & General Aviation

- Others

By Region

- North America

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Nordic Countries

- Benelux Union

- Belgium

- The Netherlands

- Luxembourg

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Southeast Asia

- Indonesia

- Thailand

- Malaysia

- Singapore

- Rest of Southeast Asia

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

About Us:

Facts & Factors is a leading market research organization offering industry expertise and scrupulous consulting services to clients for their business development. The reports and services offered by Facts and Factors are used by prestigious academic institutions, start-ups, and companies globally to measure and understand the changing international and regional business backgrounds. Our client’s/customer’s conviction on our solutions and services has pushed us in delivering always the best. Our advanced research solutions have helped them in appropriate decision-making and guidance for strategies to expand their business.

Contact Us:

Facts & Factors

A 2108, Sargam,

Nanded City,

Sinhagad Road,

Pune 411041, India

USA: +1 (347) 690-0211

Email: [email protected]

Web: https://www.fnfresearch.com