02-Sep-2022 | Facts and Factors

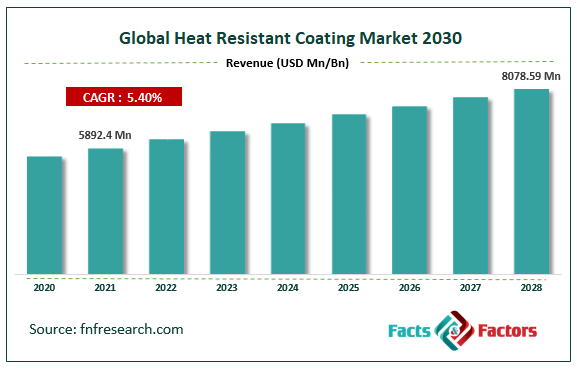

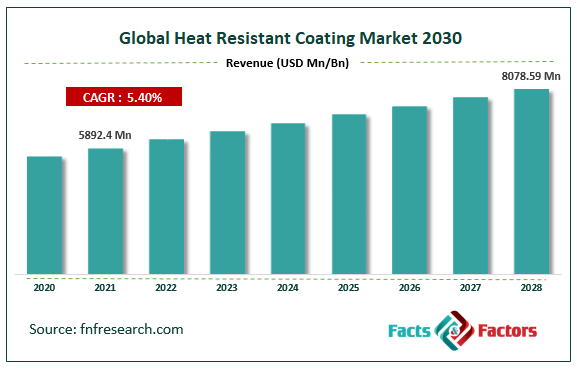

The heat resistant coating market was worth USD 5892.4 million in 2021 and is estimated to grow to USD 8078.59 million by 2028, with a compound annual growth rate (CAGR) of approximately 5.40% over the forecast period. The report analyzes the heat resistant coating market's drivers, restraints/challenges, and their effect on the demands during the projection period. In addition, the report explores emerging opportunities in the heat resistant coating market.

Broad spectrum thermal reflective coating technology is used to create heat-resistant coatings, also known as insulative coatings, that block heat radiations with a larger range of thermal energy. This coating inhibits heat conduction through the coating by 90% in the infrared and 85% in the ultraviolet due to the sun's radiation being reflected. These coatings operate in both directions. These coatings operate well in hot environments, are more resistant to corrosion and water, and hold their color better over time.

Browse the full “Heat Resistant Coating Market Size, Share, Growth Analysis Report By Resin Type (Silicone, Epoxy, Acrylic, Polyester, Modified Resins, Others), By Technology (Powder, Liquid), By Application (Automotive & Transportation, Consumer Goods, Building & Construction, Industrial, Others), and By Region - Global and Regional Industry Insights, Overview, Comprehensive Analysis, Trends, Statistical Research, Market Intelligence, Historical Data and Forecast 2022 – 2028" report at https://www.fnfresearch.com/heat-resistant-coating-market

Additionally, it aids in controlling the spread of fires. The durability, heat resistance, and corrosion resistance, among other industries, can be very advantageous to the automotive, transportation, and structural construction industries. Heat-resistant coatings are frequently used in the building and construction sector. They work to ensure that different building materials and products follow important fire safety rules and guidelines. Applying heat-resistant coatings increases public safety and aids in the suppression of flames.

Avoiding overheating of flat roofs, metal, asbestos, or outside walls is the goal of heat-resistant coating. The interiors are kept cold throughout the scorching summer because of how highly reflective it is in the solar spectrum's near-infrared (non-visible) region. The efficiency of air conditioning plants is increased by utilizing heat-resistant coating, which also has the adaptability to handle dynamic motions. There is a significant reduction in greenhouse gas emissions due to the power savings from its use in buildings. Because the paint and coatings industry is so dependent on them, raw materials play a far larger role in this industry. It is crucial to reduce the availability of raw materials. The acquisition of raw materials is in danger due to the rising trade restrictions. Especially those that employ industrial raw materials like metal, plastic, and chemicals struggle, there are many firms. In addition, market participants will have attractive opportunities due to increasing funding for new infrastructure initiatives, housing construction, and non-residential building renovations. The need for heat-resistant coatings will increase in the future due to new technical developments and greater public awareness of their advantages.

The heat resistant coating market has been segmented into resin type, technology, applications and region. The heat resistant coating market segments are based on resin type, silicone, epoxy, acrylic, polyester, modified resin, and others. The silicone resin market is predicted to develop significantly in 2021. Based on technology, the market is classified into powder and liquid. The powder category dominated the market in 2021. Based on application, the heat resistant coating market is segmented into automotive & transportation, consumer goods, building & construction, industrial, and others. The automotive and transportation industries are predicted to have the largest revenue share in 2021.

The market segments are North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. In 2021, the Asia Pacific dominated the global heat resistant coating market. The expansion's primary drivers are the transportation sector, rising FDI, new and developing economies, and low-cost labor. The service sector has grown more rapidly due to the digitization wave. The fast-growing service industry is increasing the demand for workplaces and residential properties in Asia-Pacific. However, the lack of such infrastructure in these nations is also fueling a rise in construction activity in such nations. Due to breakthroughs and technological advancements in the region, the employment of heat resistant coatings for flammable fluid pipelines is increasing dramatically due to the region's continuous fast industrialization, particularly in China, Japan, and India.

Report Scope

Report Attribute |

Details |

Market Size in 2021 |

USD 5892.4 Million |

Projected Market Size in 2028 |

USD 8078.59 Million |

CAGR Growth Rate |

5.40% CAGR |

Base Year |

2021 |

Forecast Years |

2022-2028 |

Key Market Players |

AkzoNobel N.V., Sherwin Williams Company, PPG Industries Inc., Axalta Coating Systems, Jotun A/S, Hempel A/S, Kansai Paints Co. Ltd, KCC Corporation, RPM International Inc., Tikkurila OYJ., and Others |

Key Segment |

By Resin Type, Technology, Application, and Region |

Major Regions Covered |

North America, Europe, Asia Pacific, Latin America, and the Middle East &, Africa |

Purchase Options |

Request customized purchase options to meet your research needs. Explore purchase options |

Key players in the heat resistant coating market include AkzoNobel N.V., Sherwin Williams Company, PPG Industries Inc., Axalta Coating Systems, Jotun A/S, Hempel A/S, Kansai Paints Co. Ltd, KCC Corporation, RPM International Inc., and Tikkurila OYJ.

Recent Development:

- February 2019: For new build and shop applications such as refineries, petrochemical plants, and industrial applications, PPG developed PPG Hi-temp 900 coating.

Heat Resistant Coating Market is segmented as follows:

By Resin Type:

- Silicone

- Epoxy

- Acrylic

- Polyester

- Modified Resins

- Others

By Technology:

By Application:

- Automotive & Transportation

- Consumer Goods

- Building & Construction

- Industrial

- Others

By Region

- North America

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Nordic Countries

- Benelux Union

- Belgium

- The Netherlands

- Luxembourg

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Southeast Asia

- Indonesia

- Thailand

- Malaysia

- Singapore

- Rest of Southeast Asia

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

About Us:

Facts & Factors is a leading market research organization offering industry expertise and scrupulous consulting services to clients for their business development. The reports and services offered by Facts and Factors are used by prestigious academic institutions, start-ups, and companies globally to measure and understand the changing international and regional business backgrounds. Our client’s/customer’s conviction on our solutions and services has pushed us in delivering always the best. Our advanced research solutions have helped them in appropriate decision-making and guidance for strategies to expand their business.

Contact Us:

Facts & Factors

A 2108, Sargam,

Nanded City,

Sinhagad Road,

Pune 411041, India

USA: +1-347-989-3985

Email: [email protected]

Web: https://www.fnfresearch.com